用于药物输送的纳米颗粒技术

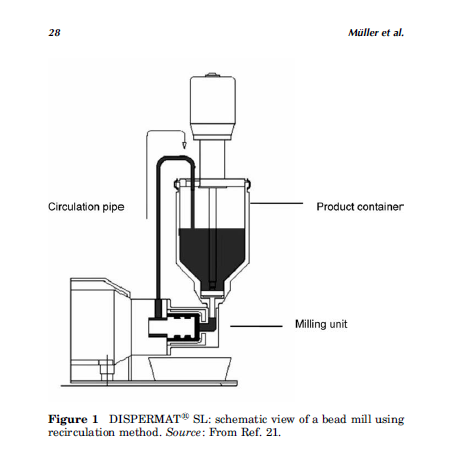

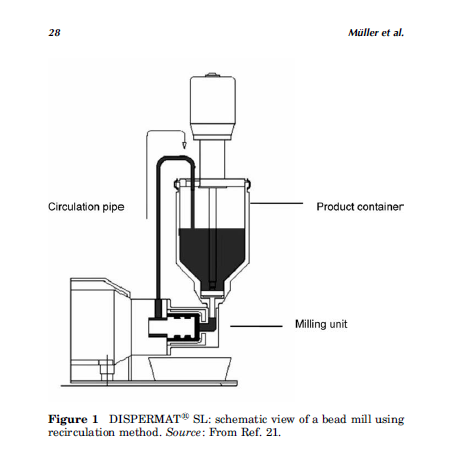

“市场上有许多珠(球)研磨机可供使用,从实验室规模到工业化生产规模的均有,产品能够大规模生产是其进入市场的一个必要条件,除了产品成本低,珠(球)研磨法的一个优点就是能够大规模生产。考虑到简便性的问题,研磨室通常设计成六角形,此时研磨室容积的76%都可以被研磨材料填充。1000L的研磨机对应760L研磨材料:氧化锆的表观密度是3.96kg/L,需要2.8t的研磨材料。图2.1给出了这个问题的解决方法。图中示出的是Dispermat SL珠(球)研磨机和外部的混悬容器。混悬液通过泵反复地通过珠(球)研磨机。这种方法减少了研磨材料的重量,但延长了研磨时间。”

Nanoparticle Technology for Drug Delivery

“There are a number of pearl mills available on the market, ranging from laboratory-scale to industrial-scale volumes. The ability for large-scale production is an essential prerequisite for the introduction of a product to the market.One advantage of the pearl mills, apart from being low-cost products, is their ability for scaling up. Assuming, for reasons of simplicity, hexagonal packaging of the milling pearls, 76% of the milling chamber volume will be filled by the pearls. In case of a 1000L mill this corresponds to 760L milling material; based on the apparent density of zircon oxide pearls being 3.69 kg/L, this corresponds to 2.8 tons of milling material.Figure 1 shows the solution for this problem, a pearl mill with an external suspension container. The suspension is continuously pumped through the pearl mill. This approach reduces the weight of the pearl mill itself, but it prolongs the milling times.”