配制水溶性差的药物

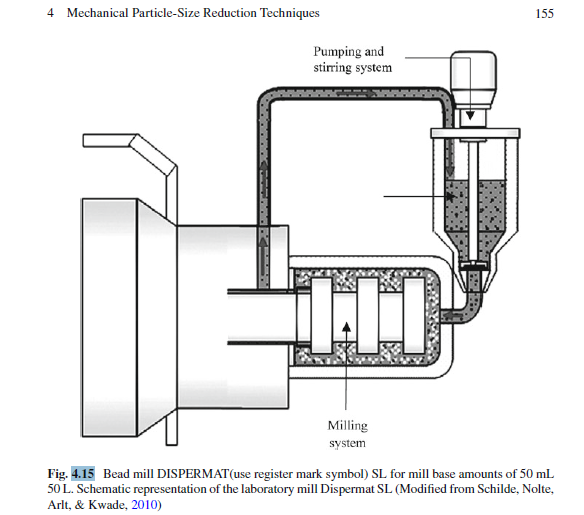

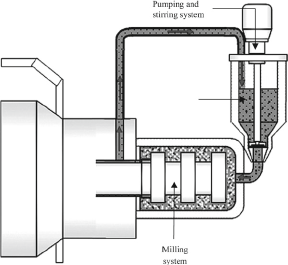

“这种类型的研磨机通过将介质(珠粒)与材料(通常是API)一起机械移动到液体中来操作。 这可以通过搅拌器或通过搅拌容器本身来完成。 珠子可以由各种材料制成; 但是,它们通常是玻璃球,陶瓷,金属或塑料。 珠粒密度可以在2,500至7,800kg / m 3之间,尺寸在0.1至10mm之间(Kwade和Schwedes 2007)。 闭式搅拌介质研磨机可以垂直或水平布置,并且通常配备有用于冷却目的的热护套。 根据腔室和搅拌器的几何形状,可以区分三种类型的磨机,即盘式搅拌器,带销针式搅拌器的中间磨机和环形间隙几何形状(图4.15)。”

卧式珠(球)磨机Dispermat SL表示研磨腔容量为50 mL- 50 l实验室用卧式研磨机SL的示意图

Formulating Poorly Water Soluble Drugs

4.3.2.2 Media (Bead) Wet-Milling

This type of mill operates by mechanically moving media (beads) together with the material (normally the API) in a liquid. This can be done either by means of a stirrer or by agitating the container itself. The beads can be made of various materials; however, they are normally glass spheres, ceramics, metal, or plastic. The bead densities can range between 2,500 and 7,800 kg/m 3 , with sizes between 0.1 and >10 mm (Kwade and Schwedes 2007 ) . Closed stirred media mills can be arranged either vertically or horizontally and are normally equipped with a thermal jacket for cooling purposes. According to the chamber and stirrer geometry, three types of mills can be distinguished, namely a disk stirrer, a medial mill with pin-counter-pin stirrer, and an annular gap geometry (Fig. 4.15 ).”