了解纳米晶体的纳米稳定剂和纳米生物相互作用

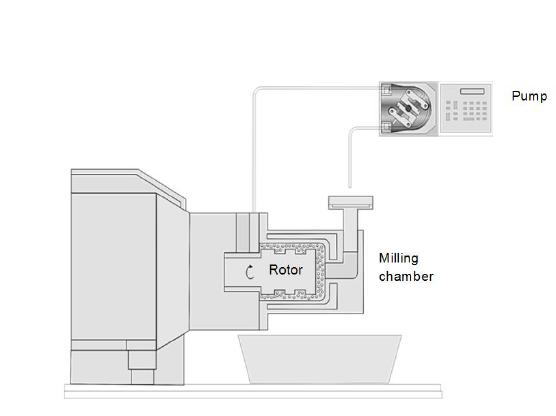

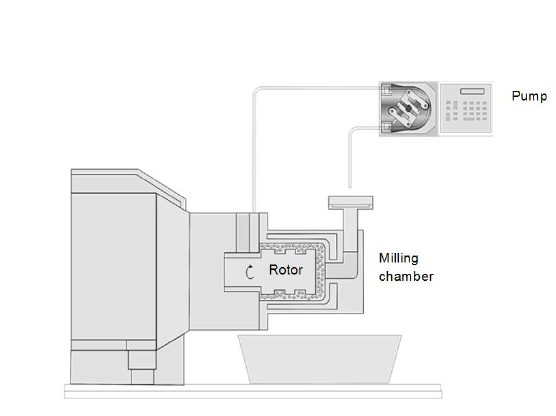

介质研磨是制药行业大规模生产纳米晶体的标准做法,使用搅拌式球(珠)磨机,如在循环模式下的卧式珠(球)磨机。市场上大多数纳米晶体产品都是采用Perrigo公司的PLC专利NanoCrystal®技术生产的。该专利的核心是采用一种具有循环药物悬浮液的卧式珠(球)磨机。在这项工作中使用实验室型的搅拌球(珠)磨机是卧式珠(球)磨机Dispermat®(图15)。

将由粗药物颗粒和稳定剂溶液组成的悬浮液与研磨珠一起保存在密闭容器中。研磨后必须将悬浮液与研磨珠分离。 因此,Dispermat®在研磨容器和出口之间具有用于循环目的的动态密封技术。 悬浮颗粒能够通过该密封间隙,同时研磨珠留在研磨腔中。因此,如果将研磨珠分离过程与行星研磨机(例如,行星研磨机必须手动去除珠粒)进行比较,就更容易实现珠粒和产品的自动分离。在珠与珠、珠与壁和珠与转子接触点之间的起始物料受到一定的作用力,这取决于接触点的性质,因此根据转子的转速、研磨时间和研磨珠尺寸,可以产生不同的颗粒粒径。

实现将颗粒粒径下降到纳米级,这项工作采用循环模式下的Dispermat®SL-C 5(德国VMA Getzmann GmbH)。所有实验的泵速为69mL / min(双重蒸馏水)。将外部冷却液体冷却至8℃并在研磨时循环通过研磨腔内。 作为密封液,使用正在进行研磨的稳定剂溶液。 转子转速设定为4,000rpm,并且对于每个实验,将10g药物用于100g最终制剂中。

循环模式下的卧式珠(球)磨机方案

Understanding nano-stabiliser and nano-bio interactions of nanocrystals

3.2.1 Media milling

Media milling is a standard practise for large scale production of nanocrystals in pharmaceutical industry, using agitated ball mills, like horizontal bead mills in recirculation mode [M?schwitzer, 2013]. Most nanocrystal products on the market are produced with the NanoCrystal® technology which is patented by the Perrigo Company PLC [US Patent 5145684]. The core of the patent is a horizontal bead mill with a circulating drug suspension. One example for the construction of an agitated ball mill on laboratory scale is the horizontal bead mill type Dispermat® which was utilised in this work (Figure 15).

The suspension, consisting of coarse drug particles and stabiliser solution, is kept in a closed vessel together with the milling beads. The suspension has to be separated from the beads after milling. Therefore, the Dispermat® has a dynamic gap between milling vessel and outlet for circulation purposes. Particles in suspension are able to pass this gap while milling beads stay in the milling chamber. Hence, an automated separation of beads and product is achieved more easily when comparing the bead separation process to, for example, a planetary mill, where the beads have to be manually removed. Starting material that gets in between bead–bead, bead-wall and bead-rotor contacts is exposed to a certain force, depending on the nature of the contact, so that depending on the rotor speed, milling time and bead size, different particle sizes can be produced.

Figure 15: Scheme of a horizontal media mill in circulating mode.

Particle size reduction to the nano-scale was accomplished, in this work, with the Dispermat® SL-C 5 (VMA Getzmann GmbH, Germany) in a circulation setup. Pump speed for all experiments was at 69 mL/min (set for double-distilled water). External cooling fluid was cooled down to 8 °C and circulated through the casing of the milling chamber while milling. As sealing liquid, the stabiliser solution for the ongoing milling was used. Rotor speed was set to 4,000 rpm and for every experiment 10 g of drug was used in 100 g of final formulation. Before milling, the drug was added to the stabiliser solution and directly homogenised with an Ultra Turrax® (Ultra Turrax® T25 basic, IKA®-Werke GmbH & Co. KG, Germany, rod of 1.7 cm diameter) for 10 seconds at 11,000 min-1 to minimise floating of the drug on the surface.”