纳米碳对环氧树脂固化的影响

3.2.1剪切混合搅拌

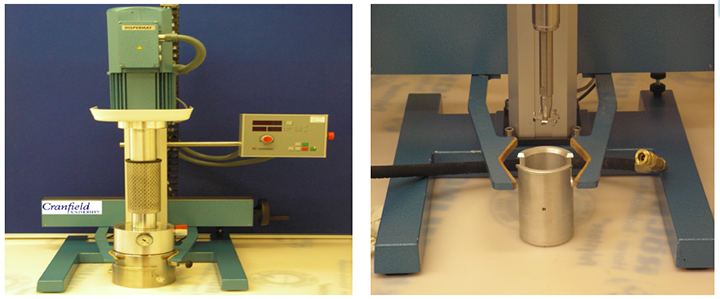

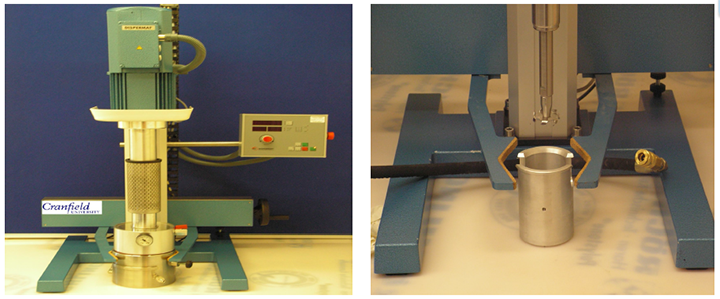

使用DISPERMAT®CNF2型号的剪切混合搅拌机将碳纳米颗粒分散在液体环氧体系中。 紧凑型驱动单元包含三相电机和单独驱动的低噪音通风。中央夹紧系统 - 安全装置的一部分 - 提供了一种安全且简单的方法,可将分散容器牢固地固定到位。容器放置在夹臂之间的实验室工作台上,并在臂被拧紧时自动置中。控制面板有一个数字显示屏,允许操作员在速度,扭矩或时间值之间自由切换。安全设备功能也显示在数字显示屏上(参见图3.4)。

图3.4:用于分散的DISPERMAT®CNF2高剪切混合器

Hyperion多壁碳纳米管和炭黑颗粒

剪切混合搅拌过程取决于剪切螺旋桨距液体表面的距离。螺旋桨通常放置在距离浆料底部的填充树脂总高度的近2/3处。该规范允许碳纳米颗粒在环氧系统中更好地混合和均匀分布。通过在树脂中引入碳纳米颗粒,然后添加固化剂来进行混合搅拌过程。 高剪切混合器用于将Hyperion多壁碳纳米管和炭黑颗粒掺入MY 750 / HY 5922树脂体系中。

3.2.1剪切混合搅拌

使用DISPERMAT®CNF2型号的剪切混合搅拌机将碳纳米颗粒分散在液体环氧体系中。 紧凑型驱动单元包含三相电机和单独驱动的低噪音通风。中央夹紧系统 - 安全装置的一部分 - 提供了一种安全且简单的方法,可将分散容器牢固地固定到位。容器放置在夹臂之间的实验室工作台上,并在臂被拧紧时自动置中。控制面板有一个数字显示屏,允许操作员在速度,扭矩或时间值之间自由切换。安全设备功能也显示在数字显示屏上(参见图3.4)。

图3.4:用于分散的DISPERMAT®CNF2高剪切分散机

Hyperion多壁碳纳米管和炭黑颗粒

剪切混合搅拌过程取决于剪切螺旋桨距液体表面的距离。螺旋桨通常放置在距离浆料底部的填充树脂总高度的近2/3处。该规范允许碳纳米颗粒在环氧系统中更好地混合和均匀分布。通过在树脂中引入碳纳米颗粒,然后添加固化剂来进行混合搅拌过程。 高剪切混合器用于将Hyperion多壁碳纳米管和炭黑颗粒掺入MY 750 / HY 5922树脂体系中。

Effect of carbon nanoparticle addition on epoxy cure

3.2.1 Shear mixing

A DISPERMAT® CN F2 model shear mixer was used to disperse the carbon nanoparticles in the liquid epoxy system. The compact drive unit contains a three phase motor and separately driven low noise ventilation. The central clamping system – part of the safety device – offers a safe and simple way of holding the dispersion container securely in position. The container is placed on the laboratory bench between the clamping arms and is automatically centered as the arms are tightened. The control panel has a digital display which allows the operator to switch between values for speed, torque or time. The safety device functions are also indicated on the digital display (see figure 3.4).

Figure 3.4: DISPERMAT® CN F2 high shear mixer used to disperse the Hyperion multi-walled carbon nanotubes and carbon black particles

The shear mixing process depends on the distance of the shear propeller from the surface of the liquid batch. The propeller is usually placed at a distance of almost 2/3 of the total height of the filled resin from the bottom of the batch. This specification allows for a better mixing and an even distribution of the carbon nanoparticles in the epoxy system. The mixing process takes place with the incorporation of carbon nanoparticles in the resin, and then the addition of the curing agent. The high shear mixer was utilised for the incorporation of Hyperion multiwalled carbon nanotubes and carbon black particles into the MY 750 / HY 5922 resin system.