介绍湿法超细珠(球)磨机的特点

2.分析珠(球)磨机中的研磨过程的特征

珠(球)磨机是一种用湿法进行超微细粉碎的设备。该珠(球)磨机由一个带轴的垂直(或水平)研磨室组成。该腔室包含一个转子,该转子由一个带有圆盘或杆的轴组成。腔体充满了70-80%的玄武岩,玻璃或钢珠。当转子旋转时,材料的固体颗粒由于在研磨的主体上相互摩擦而被压碎。生产型的珠(球)磨机以周期性,连续式或循环式工作。该研磨机具有筛筒或狭缝以分离研磨珠与悬浮液。产品的最终粒径可以小于1μm(Rowe W.B.,2014; Salenko YU。,2008; Grining K.,Tarasenko M.,2017)。珠磨机中的精细研磨过程取决于许多操作参数。研究表明,重要因素包括:机械能,比能耗,研磨体碰撞能量,研磨体与产品的有效碰撞次数,以及颗粒在研磨机中的停留时间(Mende S. ,Rappl M.,2014; Rowe WB,2014)。此外,在研磨时,物质表面的气体和液体残余物的解吸被破碎,结果固体的表面积发生变化(Dr?gemeierR。,Leschonski K.,1994)。机械能是从转子通过珠子传递到悬浮液的能量。引入系统的能量越多,破坏强结块的可能性就越大(Dr?gemeierR。,Leschonski K.,1994)。能量可以以多种方式引入:具有高转子速度和低扭矩,或反之亦然,在高扭矩和低旋转速度下(Nakach,M.,Authelin,J.,Agut,C。2017)。

FEATURES OF A ULTRA-FINE GRINDING BY WET METHOD IN BEAD MILLS

2. Analysis of the features of the grinding process in a bead mill

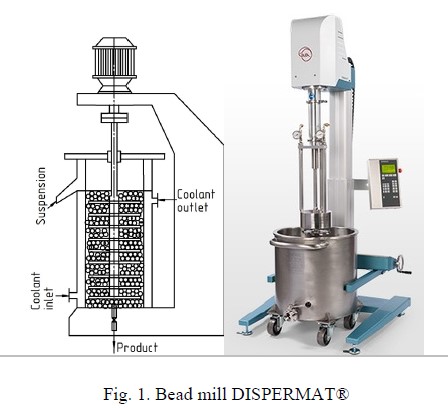

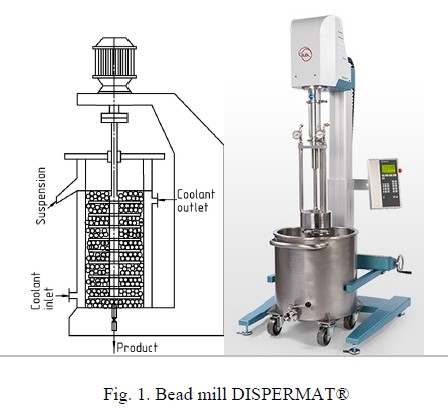

The bead mill is an equipment for thin and superfine grinding, which occurs by a wet method.

The mill consists of a vertical (or horizontal) grinding chamber with a shirt. The chamber contains a rotor which consist of a shaft with disks or rods attached to it. The camera is filled with 70-80% beads from a basalt, glass or steel. When the rotor rotates, the solid particles of the material are crushed as a result of the friction on the body that is grinding, and each other. An industrial bead mill works in periodic, continuous or circulating modes. The mill has a sieve cartridge or a slit to separate the beads from the suspension. The size of the crushed product can reach less than 1 μm (Rowe W.B., 2014; Salenko YU., 2008; Grining K., Tarasenko M., 2017).The process of fine grinding in the bead mills depend to many operating parameters. The studies have shown that important factors are: mechanical energy, specific energy consumption, energy of collisions of grinding bodies, the number of effective collisions of grinding bodies with the product, as well as the residence time of particles in the mill (Mende S.,Rappl M., 2014; Rowe W.B.,2014). In addition, at grinding the desorption of gas and liquid residues from the surface of the substance is shattered, as a result the surface area of the solid changes (Dr?gemeier R.,Leschonski K., 1994).

Mechanical energy is the energy that is transmitted from the rotor through the beads to the suspension. The more energy is introduced into the system, the greater the likelihood of the destruction of strong agglomerates(Dr?gemeier R., Leschonski K., 1994). Energy can be introduced in several ways: with high rotor speed and low torque, or vice versa, at high torque and low rotational speed (Nakach, M., Authelin,J., Agut, C. 2017)